Η πιο λεπτομερής στρατηγική αγορών

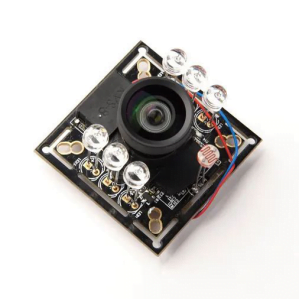

The industrial camera is one of the core devices in the machine vision system. Πριν επιλέξετε μια κάμερα για μια εφαρμογή, the system design engineer needs to fully understand the parameters and indicators of the camera to select the most suitable industrial camera for the application and realize the optimization of cost performance. What are the main parameters to know before choosing a camera? Let’s take a look:

一、 Ανάλυση

Q: How to determine the resolution to be selected?

A: Resolution is the most basic parameter of the camera, which is determined by the chip resolution used by the camera. When collecting images, the resolution of the camera has a great impact on the detection accuracy. When imaging the same large field of view (scene range), the higher the resolution, the more obvious the display of details.

Common industrial array cameras have resolutions of 5 εκατομμύριο, 12 εκατομμύριο, 65 εκατομμύριο, και τα λοιπά. For a linear array camera, the resolution is the number of pixels in the horizontal direction of the sensor, usually 2K, 4Κ, 8Κ, 16Κ, και τα λοιπά.

The choice of resolution is mainly to estimate the size of the field of view according to the size of the object to be measured, and then determine the required industrial camera resolution in combination with the accuracy requirements.

Για παράδειγμα, if the object size is 50mm, the field of vision can be estimated as 50 × 1.2=60mm, if the accuracy of a single pixel is required to be 0.02mm, the resolution is 50 × 1.2/0.02=3K.

Note: The higher the resolution is, the better the camera is. The higher the resolution is, the larger the amount of image data will be, and the more complex the later algorithm processing will be.

二、 Frame rate/line rate

Q: What is the maximum frame rate/line rate?

A: The maximum frame rate/line frequency of an industrial camera represents the rate at which the camera collects images per unit time.

Generally, the frame rate is relative to the area array industrial camera, and the unit is fps, such as 181fps, that is, the camera can collect up to 181 frames of images per second.

The line frequency is relative to the linear array industrial camera, and the unit is kHz. Για παράδειγμα, 80kHz, that is, the camera can collect up to 80000 lines of image data per second.

三、 Pixel size

Q: What are the effects of pixel size on imaging?

A: Pixel is the image unit, which is the smallest unit of digital image.

The pixel size and the number of pixels (resolution) jointly determine the size of the camera target. Generally, the pixel size of industrial cameras is 2 μ m~14 μ m.

The pixel size reflects the chip’s response to light to some extent. Generally, the larger the pixel size is, the more photons can be received, and the more charges can be generated under the same lighting conditions and exposure time.

四、 Pixel depth

Q: Is greater pixel depth better?

A: Pixel depth refers to the number of bits of each pixel data, usually expressed in bits. In general, each pixel has many bits and strong ability to express image details. The gray scale value of this pixel is richer and finer, and the gray scale depth of the pixel is deeper. But at the same time, the larger the amount of data is, which affects the image processing speed of the system. Therefore, careful selection is also required.

The common ones are 8bit, 10bit and 12bit. The resolution and pixel depth together determine the size of the image. Για παράδειγμα, for 5 million pixels with a pixel depth of 8 bits, the whole picture should have 2560 × two thousand and forty-eight × 8/8/1024/1024=5MB.

五、 Dynamic range

Q: What is the dynamic range?

A: The dynamic range is used to describe the gray level that can be distinguished by each pixel. The wide dynamic range can enable the details of the light field and dark field in the scene to be recorded clearly at the same time.

The larger the dynamic range value, the wider the range in which the industrial camera can take pictures of the object.

六、Signal-to-noise ratio

Q: What are the noises of industrial cameras? Why is the higher the signal-to-noise ratio, the better?

A: The noise of the industrial camera refers to the signal that is not expected to be collected during the imaging process but is outside the actual imaging target.

According to the noise in cameras defined in the EMVA 1288 standard of the European Machine Vision Association (EMVA), there are generally two categories: one is the shot noise caused by effective signals, which is the same for any camera and unavoidable; The other is the intrinsic signal independent noise of the camera, which is caused by the image sensor readout circuit, camera signal processing and amplification circuit. The intrinsic noise of each camera is different.

The signal-to-noise ratio of the camera is defined as the ratio of signal to noise in the image (the ratio of the average gray value of the effective signal to the root mean square of the noise), where the signal can be calculated by multiplying the light intensity by the quantum efficiency by the integration time, while the noise refers to the sum of the noises generated by all parts in the imaging process; The higher the signal-to-noise ratio, the less clutter mixed in the signal, the higher the image quality, the cleaner the picture, and no noise interference can be seen (manifested as “particles” και “snowflakes”); If the signal-to-noise ratio is smaller, more “particles” και “snowflakes” may appear on the image, which will affect the image quality.

七、 Exposure time

Q: Is the exposure time of the camera long or short?

A: The exposure time is the time when the shutter is to be opened to project light onto the sensitive surface of the photographic sensitive material; Depending on the sensitivity of the photosensitive material and the illumination on the photosensitive surface; The longer the exposure time, the greater the light inflow, which is suitable for poor light conditions; Short exposure time is suitable for better light conditions.

八、 Camera interface

Q: What interfaces do industrial cameras have?

A: Industrial cameras usually have three basic interfaces: power interface, data interface and lens interface.

Power interface: As the name implies, it is used as the camera power input interface.

Data interface: According to different interface standards, the common data interfaces of industrial cameras include GigE, Camera Link, USB3.0, CoaXPress, και τα λοιπά.

Lens interface: There are many types of lens interfaces for industrial cameras, including C interface, CS interface, F interface, M42 interface, M72 interface, και τα λοιπά.

Founded in 2015, Shenzhen Jinshikang Technology Co., Ε.Π.Ε. specializes in providing various camera module products such as monocular and binocular cameras. After years of development, it has accumulated profound experience in video capture, video intelligent analysis, and vehicle electronic technology.

It has independently developed various differentiated camera modules such as object recognition, face recognition, iris recognition, and is widely used in new retail, face recognition, intelligent monitoring, industrial applications, and various image schemes. JSK is a high-tech enterprise integrating R&D, production, sales and service.

Its products are sold at home and abroad and become the designated supplier of many listed companies. Relevant module products can be customized and developed according to the actual requirements of customers. Welcome camera module manufacturers and partners to visit our company and discuss cooperation.

The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy The most detailed purchasing strategy